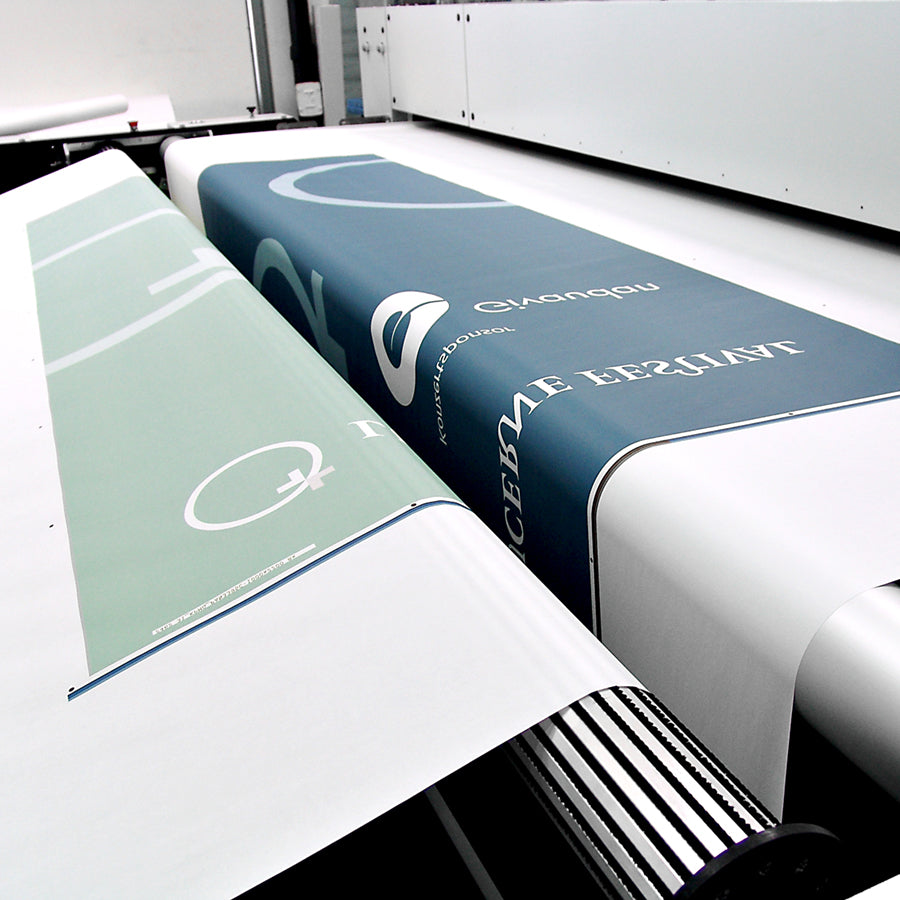

With sublimation printing, a motif is first printed in reverse using transfer paper, then placed on the final material and heated to up to 200 °C using a thermal transfer press.

Due to the temperature, the colors sublimate and penetrate the fibres. The colors are so in the fabric. The motif smooth, wear-resistant and durable. Because the colors penetrate the fabric, there are no disturbing light reflections.

In addition, the colors are very intense and hardly fade. The carrier material is washable, non-iron and does not cause any creases.

Another advantage is the print sharpness, images and photos are transmitted in the best quality. The sublimation printing process is sustainable because no solvents are required and the material is odorless.

Which materials are printed?

The carrier material is polyester, i.e. a fabric made of plastic fibers. While natural materials like cotton burn at high temperatures, polyester begins to melt when exposed to heat. The pores in the fabric open and the colors are in the fabric of the carrier material.

Our color palette

Conventional sublimation printers have a color palette of 4 colors such as black, magenta, yellow and cyan. The sublimation printing process at CCS has a wider range of 7 colors. What leads to an even better quality of the prints is particularly important when printing skin tones and particularly fine color gradients.

Do you feel inspired to implement your new projects? Then make an appointment with our CCS team right away. We are happy to help.