We not only design spaces with our products, but also a sustainable future for future generations.

sondern auch eine nachhaltige Zukunft für kommende Generationen.

Solvent-free and environmentally friendly colors

Recycled and recyclable textiles

Short procurement routes to suppliers

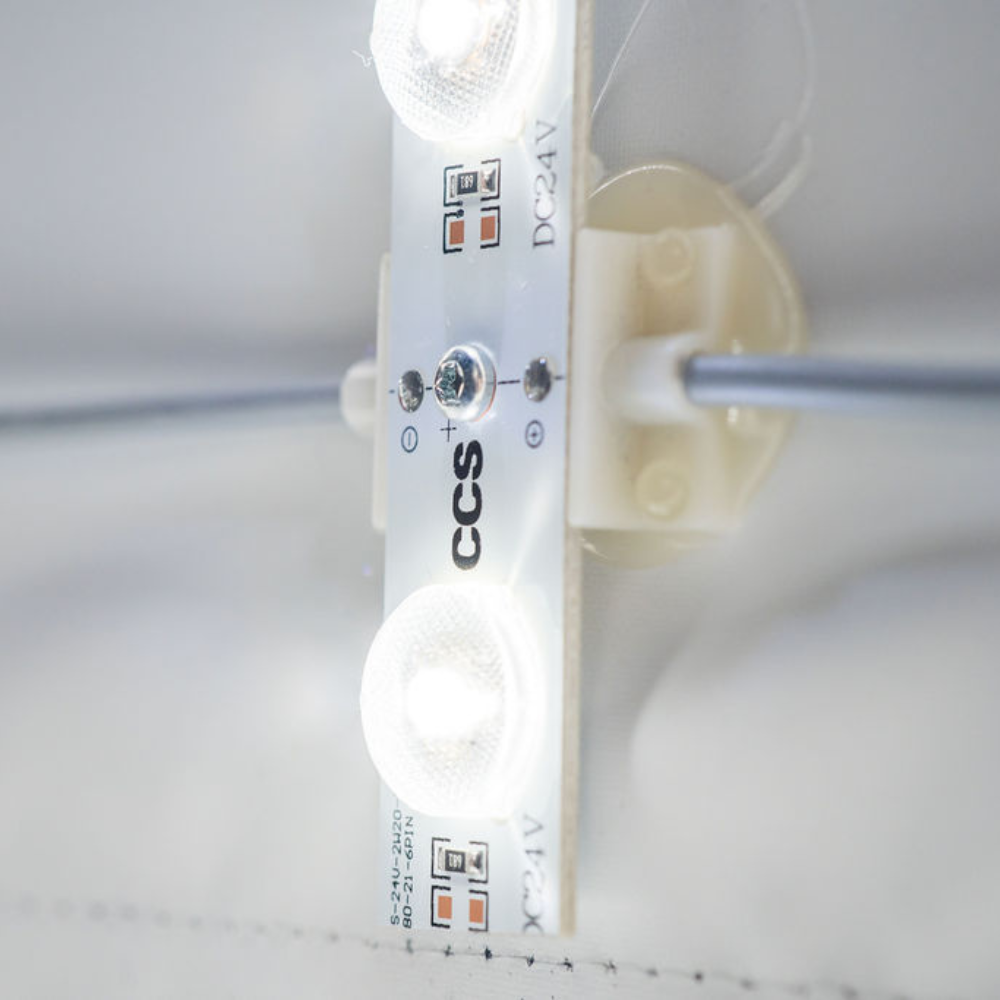

Energy saving technologies

High quality and long lasting products

Sustainable silicone replacement piping

Low shipping and storage quantities

Local production in Düsseldorf

Smart technologies for our customers

CCS focuses on innovation for sustainability in various areas. From the integration of energy-efficient LEDs to our solvent-free printing inks to our piping made of plasticizer-free silicone rubber, we consider the entire life cycle of our products.

Long-lasting and sustainable products

Our frames and light boxes are designed to last a long time and go through many assembly and disassembly cycles. This not only means that our frames are durable, but also that they themselves can be recycled at the end of their life cycle.

Save storage and shipping costs with us

Since our large textile prints can be folded without creases and our frame system works on a modular principle, we save a lot of packaging material and need little space for delivery and storage. It's hard to believe that we turn 300m² of prints into less than 1m² of shipping and storage space.

Our recycling process for textiles

15 PET bottles = 1m² textile

Only post-consumer PET is used for our PET. The raw materials for polyester production come primarily from the EU with short delivery routes. The process is certified by ISO 9001, ISO 50002 and is always checked for water hazards. The finishing of PET textiles is already taking place based on future standards. 100% of production takes place in Germany and is 100% PVC-free.

Step 1

Plastic becomes granules

For the recycling process, PET bottles are melted down into PET chips using an innovative process. This step is crucial as it forms the basis for the sustainable production of our fabrics. By converting used plastic into fine granules, we are setting an example for protecting our environment.

step 2

From PET chips to yarn

The melted PET chips are further processed by spinning them into yarn. This yarn is at the heart of our recycled polyester fabric. The spinning process is crucial to ensure that the fibers are uniform and of high quality. The resulting yarn is not only sustainable, but also versatile to meet a wide range of textile requirements.

step 3

From yarn to polyester fabric

The spun yarn is finally processed into our high-quality polyester fabric. We attach great importance to ensuring that this material meets the strict requirements of the OEKO-TEX Standard 100. The recycled polyester fabric is characterized by its softly flowing, tightly woven and closed surface. It is lightfast and water-resistant, which makes it particularly suitable for textile stretcher frames, acoustic pictures and indoor advertising banners.

Sustainability at CCS Fabric Frame: responsibility for a green future

At CCS Fabric Frame, sustainability is not just a principle, but an integral part of our corporate philosophy. We are aware of our responsibility towards the environment and do everything we can to implement sustainable processes in all our business areas.

Recyclable materials for green products

Our commitment to the environment is reflected in our choice of materials. The aluminum frames we use are made from high-quality, recyclable materials. This not only enables us to conserve natural resources, but also reduces the ecological footprint of our products.

Durability as the key to conserving resources

Wir setzen auf Langlebigkeit als zentrales Element unserer Raumausstattungslösungen. Unsere Aluminiumrahmen sind nicht nur stabil und robust, sondern auch auf wahre Langlebigkeit ausgelegt. Durch die Investition in qualitativ hochwertige, langlebige Produkte minimieren wir gemeinsam mit unseren Kunden den Bedarf an regelmäßigem Austausch und reduzieren somit Abfälle.

Environmentally friendly production practices

Our in-house production in Düsseldorf is subject to strict environmental regulations to ensure that our manufacturing processes are as environmentally friendly as possible. We rely on energy-efficient technologies and recycling processes to minimize waste and reduce energy consumption. This is a further step towards a sustainable and resource-saving future.

Committed partnerships for green solutions

CCS Fabric Frame maintains close partnerships with suppliers who are also committed to providing sustainable and environmentally friendly materials. Together, we are committed to transparent supply chains to ensure that our products not only meet our high standards, but are also manufactured in an ethically and environmentally responsible manner.

We attain our ecological footprint

Our sustainability efforts are more than just a commitment - they are an expression of our mission to make a positive change. At CCS Fabric Frame, we believe that every company has the opportunity to contribute to a more sustainable future through sustainable choices. We are continually committed to developing innovative solutions that not only meet the needs of our customers, but also protect the planet.

Contact us for sustainable interior design

Would you like to find out more about how you can create sustainable interior design solutions with CCS Fabric Frame and are you interested in our products? We are happy to provide you with more information about our environmentally friendly products and processes. Together we can design your working environment - and thus a greener and more sustainable future.